Philippine Defense Today (Adroth.ph)

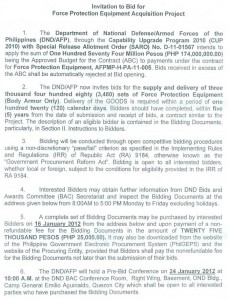

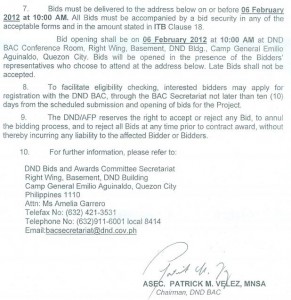

In Defense of the Republic of the PhilippinesThe following article is the rationale for the following Facebook group: https://www.facebook.com/groups/180853572015613/

The Lockheed (not Lockheed-Martin) C-130 Hercules transport aircraft is the largest airlift asset in the Philippine Air Force (PAF). It is the Philippine government’s most capable means of moving personnel and material for everything from combat deployments to disaster response. It provides the “timely” in “timely response”, therefore it is in the public’s interest that they be properly funded, operated, and maintained.

These aircraft, however, have proven to be problematic to operate in significant numbers. The loss of foreign aid as a result of expulsion of the US bases in the early 90’s has had a detrimental effect on the PAF’s budgetary condition as a whole with a corresponding impact on the Hercules fleet. For extended periods in recent post-Clark/Subic history the PAF’s tactical lift capabilities, particularly those of the 220th Airlift Wing, have hinged on solitary C-130s. This is an unacceptable state of affairs.

If the PAF, particularly the 220th Airlift Wing, is to expect the long term political and fiscal support it needs to operate these aircraft sufficient numbers, it must make its case to the Filipino voters. It must effectively articulate its needs, and inspire the people’s trust and confidence.

That trust must be earned. If the PAF is to be entrusted with the billions of pesos it needs to fulfill its mandate – money that must be taken away from roads, schools, health care programs to serve the competing BUT EQUALLY IMPORTANT defense needs of the Republic — it must be able to show the Filipino taxpayer that it is a responsible steward of those funds.

This page was created to help foster that trust through frank, unvarnished, discussion about the following:

- Facts about this category of aircraft and the challenges in keeping them operational

- Accounts of existing problems surrounding these aircraft

- Solutions . . . solutions . . . solutions

The underlying belief behind this page is that there remain honorable, competent, personnel within the Armed Forces of the Philippines that seek do to what is right. They need our help.

Dallas transfer to PH under congressional review

Sunday , 29, January 2012 Philippine Navy, WHEC Leave a commentThe United States Department of State issued a press release about the recently concluded US-PH Strategic Dialogue that included the following notation about the transfer of the USCGC Dallas to the Philippines:

Toward a Deeper Alliance: United States-Philippines Bilateral Cooperation

Office of the Spokesperson

Washington, DC

January 27, 2012< Edited >

Defense and Security Cooperation

< Edited >

The United States transferred the U.S. Coast Guard cutter Hamilton, now the BRP Gregorio Del Pilar, to the Philippine Navy, supporting Philippine maritime domain awareness. The transfer of a second cutter is pending U.S. Congressional review;

< Edited >

All transfers of defense technology, or any other export of items with military uses, are subject to congressional oversight. Defense Security Cooperation Agency (DSCA) documentation describes this control as follows:

All sales of defense articles and services are subject to similar technology release approvals, end-use monitoring and retransfer agreements, and congressional review and approval.

Open house for PF-15

Sunday , 29, January 2012 BRP Gregorio del Pilar (PF-15), Philippine Navy, WHEC Leave a commentThe Philippine Information Agency announced (see here) that the Philippine Navy will conduct an open house for the BRP Gregorio del Pilar (PF-15) on February 5, 2012 the Puerto Princessa Anchorage Area. The PF-15 arrived in Palawan on the 25th of December, 2011 and has since been patrolling the waters around the KIG.

PF-15 to perform naval gunfire test

Sunday , 22, January 2012 BRP Gregorio del Pilar (PF-15), Philippine Navy, Ships, WHEC Leave a commentBRP Gregorio del Pilar (PF-15), the Philippine Navy flagship, will perform a naval gunfire test on the 24th and 25th of January, west of Tubbataha Reef, Palawan. Details are available on the following Notice to Mariners (NOTAM):

Notice To Mariners No. 009-2012

Notice is hereby given to all mariners and other parties concerned that:1.Reference: Philippine Navy Radio Message Cite NOCB-0112-075

2.The Philippine Navy Vessel PF15 will conduct Naval Gun Test Firing on 24-25

January, 2012 from 8:00 A.M. to 5:00 P.M. at vicinity 35 Nautical Miles West of

Tubbataha Reef, Palawan< Edited >

3.In this connection, all ships/watercrafts transiting the vicinity of the

abovementioned areas are advised to take necessary precautionary measures.4.The cooperation of all concerned in effecting widest dissemination of this

information is requested.

Update: CUP Phase 2 projects

Friday , 13, January 2012 81mm mortar, AFP modernization, Artillery, MPAC, Philippine Army, Philippine Navy, Ships Leave a commentThe Philippine Star published the following figures and delivery dates for the indicated CUP Phase 2 projects. An older PIA article, however, stated that the total number of rocket launchers was “335”

| Project | Quantity | Value | Expected delivery date |

| Multi-purpose rocket launcher | 335 | P37,440,000.00 | October 2012 |

| 81mm mortar with ammunition | 100 units w/ 2,000 rounds | P190,320,000.00 | August 2012 |

| Multi-Purpose Assault Craft (MPAC) Lot 2 | 3 | P268,990,000.00 | November 2012 |

Statement of Work for F-16 Depot Level Maintenance

Sunday , 8, January 2012 Uncategorized Leave a commentThe following Statement of Work for F-16 Depot Level Maintenance was taken from the following posting on FedBizOpps.com:

F-16 Depot Maintenance Services Support for PACAF

Solicitation Number: FA8232-12-R-PACAF

Agency: Department of the Air Force

Office: Air Force Materiel Command

Location: Hill AFB OO-ALC

A copy of the document itself is available here.

Depot Level Maintenance (DLM) is defined as:

http://www.law.cornell.edu/uscode/usc_sec_10_00002460—-000-.html

. . . the term “depot-level maintenance and repair” means (except as provided in subsection (b)) material maintenance or repair requiring the overhaul, upgrading, or rebuilding of parts, assemblies, or subassemblies, and the testing and reclamation of equipment as necessary, regardless of the source of funds for the maintenance or repair or the location at which the maintenance or repair is performed. The term includes:

(1) all aspects of software maintenance classified by the Department of Defense as of July 1, 1995, as depot-level maintenance and repair, and

(2) interim contractor support or contractor logistics support (or any similar contractor support), to the extent that such support is for the performance of services described in the preceding sentence.

Watchers of the PAF effort to acquire F-16 would find this document interesting for the information it provides about the standards and AF technical orders associated with this procedure. It provides insight into the range of skill-sets that PAF needs to develop to operate this aircraft.

| Standards | ||

| MIL-HDBK-514 | Operational Safety, Suitability, and Effectiveness | |

| MIL-STD-882D | Standard Practice for System Safety | |

| MIL-STD-1686C | Electronic Discharge Control Pgm for Protection of Electrical and Electronic Part Assemblies and Equipment | |

| NAS-410 | Nondestructive Testing Personnel Qualification and Certification (Eddy Current, Liquid Penetrant, Magnetic Particle, Radiographic, Ultrasonic) | |

| NAS-412 | Foreign Object Damage/Foreign Object Debris Prevention | |

| T.O. 1-1A-15 | General Maintenance Instructions for Support Equipment | |

| AFI 21-101 | Aircraft and Equipment Maintenance Management | |

| AFI 21-101_AFMCSUP_I | Aircraft and Equipment Maintenance Management | |

| DCMA INST 8210.1 | Contract’s Flight and Ground Operations | |

| DCMA INST 8210.2 | Aircraft Operations | |

| 309 MXSG OI 21-410 | Nondestructive Inspection | |

| Specifications | ||

| AS9100 | Quality Management Systems – Aerospace – Requirements | |

| DoD 5100.1-R | Personnel Security Program Regulation | |

| ISO 9001:2000 | Quality Systems-Model for Quality Assurance in Production, Installation and Servicing | |

| ISO 9002:1994 | Quality Systems-Model for Quality Assurance in Production, Installation, and Servicing | |

| Technical Orders | ||

| TO 00-5-1 | AF Technical Order System | |

| TO 00-5-15 | AF Time Compliance Technical Order System | |

| TO 00-20 Series | Maintenance Management System | |

| TO 00-25-172 | Ground Servicing of A/C and Static Grounding/Bonding | |

| TO 00-35D-54 | USAF Material Deficiency Reporting and Investigating System | |

| TO 1-1-3 | Inspection and Repair of Integral Tanks and Fuel Cells | |

| TO 1-1-691 | Aircraft Cleaning | |

| TO 1-1-8 | Application and Removal of Organic Coatings, Aerospace and Non-Aerospace Equipment | |

| TO 1-1-17 | Storage of Aircraft and Missile Systems | |

| TO 1-1A-1 | General Manual for Structural Repair | |

| TO 1-1A-8 | Engineering Manual Series – Aircraft and Missile Repair – Structural Hardware | |

| TO 1-1A-9 | Engineering Manual Series for Aircraft Repair – Aerospace Metals – General Data and Usage Factors | |

| TO 1-1A-12 | Maintenance and Repair of Plastics | |

| TO 1-1A-14 | Installation of Practices, Aircraft Electrical and Electronics Wiring | |

| TO 1-1B-40 | Weight and Balance Data | |

| TO 1-1B-50 | Basic Technical Order for USAF Aircraft Weight and Balance | |

| TO 1F-16CG-01 | List of Applicable Publications, F-16C/D aircraft, Block 40/50 | |

| TO 1F-16CG-06 Series

TO 1F-16CJ-2 Series |

A/C Maintenance-Work Unit Code Manual F-16C/D Aircraft | |

| TO 1F-16CG-2 Series

TO 1F-16CJ-2 Series |

Maintenance Instructions Manual Series F-16C/D Aircraft | |

| TO 1F-16CG-3 Series

TO 1F-16CJ-3 Series |

Structural Repair, Structures F-16C/D Aircraft | |

| TO 1F-16CG-4 Series

TO 1F-16CJ-4 Series |

Illustrated Parts Breakdown Introduction | |

| TO 1F-16CG-5-1/-2 | Basic Weight Checklist Weight and Balance, F-16 C/D Aircraft | |

| TO 1F-16CG-6-11

TO 1F-16CJ-6-11 |

Scheduled Inspection and Maintenance Requirements, F-16C/D Aircraft | |

| TO 1F-16CG-21-WA

TO 1F-16CJ-21-WA |

A/C Equipment Inventory List, Master Guide, F-16C/D Aircraft | |

| TO 1F-16CG-23

TO 1F-16CJ-23 |

Corrosion Control, F-16C/D Aircraft | |

| TO 1F-16C-33-1/-2 | Non-nuclear Munitions Basic Information & Loading Procedures | |

| TO 1F-16C-36 | Non Destructive Inspection, F-16C/D |

Shipspotting: USCGC Dallas (WHEC-716)

Saturday , 7, January 2012 Philippine Navy, WHEC Leave a commentCoast Guard Island’s proximity to a public marina made shipspotting efforts for the USCGC Hamilton relatively easy. Unless the transfer of the USCGC Dallas takes place at the same venue, observation of the transfer at WHEC-176’s current home port will present challenges for PN modernization watchers.

Based on the following references, WHEC-716 is based at the Charleston Marine Support Facility.

http://www.d7publicaffairs.com/external/content/document/586/164869/1/NESU.pdf

CHARLESTON, S.C. — Pier Papa at the Coast Guard Vessel Support Facility Charleston with Coast Guard Cutters Dallas, Gallatin, and Oak, and NOAA ships Ron Brown and Nancy Foster

http://www.moc.noaa.gov/port.htm

The Charleston Marine Support Facility is located on the former Charleston Naval Base and is located with the USCG Naval Engineering Support Unit Charleston, in Charleston, South Carolina. The facility is the home port of the NOAA Ships Ronald H. Brown and Nancy Foster.

The Charleston Marine Facility consists of an 800 square ft. warehouse, a 650 ft. Pier and associated parking. The former naval facilities are of good quality and room exists for an increased NOAA presence in Charleston. The Charleston Marine Support Facility is managed by the Marine Operations Center – Atlantic.

The Charleston Marine Support Facility address is:

Charleston Marine Support Facility

1050 Register Street

Charleston, SC 29405-2421

There is no way to know if the ship below is either the USCGC Dallas or the USCGC Gallatin, which are both stationed in South Carolina. However the Google Earth images below, dated 1989, at least identify the anchorage described above.

|

|

|

|

JSOTF-P construction project in Camp Basilio Navarro, Zamboanga

Saturday , 7, January 2012 AFP modernization, Bases and Support Systems Development (BSSD) Leave a commentFedBizOpps.com, US government equivalent to PhilGEPS, published a bid invitation to repave a road within Camp General Basilio Navarro in Zamboanga City, headquarters of Naval Forces Western Mindanao (NAVFORWEM). The Joint Special Operations Task Force (JSOTF) – Philippines is facilitating the project. Details are available at the following link.

Excerpts from the invitation

Repave Naval Station Road – Zamboanga City – Camp Navarro, Philippines

The contractor will provide all plant, labor, and materials required to repave the Naval Station Road at Zamboanga City – Camp Navarro, Philippines, in accordance with . . . Statement of Work.

The estimated magnitude of this project is between $25,000.00 and $100,000.00.

This is a construction project which will be performed in the Republic of the Philippines, Camp Navarro – Zamboanga City. The purpose of this project is to demolish, excavate and dispose of the existing asphalt and concrete road, which covers an area of approximately 1,900 square meters, in accordance with local laws and ordinances. The contractor is then required apply sub-base material and compaction to 95% maximum density; and, install a 150 mm thick reinforced concrete cover, with a rough broom finish. The successfull offeror will be required to provide appropriate warning signs and flagmen throughout the construction process. The request for quotation will be issued 2 January 2012; and, quotations must be submitted no later than 10 January 2012 at 4:30 PM Philippine Standard Time (PST). Pre-proposal site visit is tentatively scheduled 7 January 2012 at 2:00 PM PST. Contact the Contracting Officer at jsotfp.cco@gmail.com to RSVP for the Pre-proposal site visit. Prospective offerors will be required to submit concept drawings and plans with their quotations. The magnitude of this project, in accordance with FAR 36.204, is between $25,000 and $100,000. Performance is outside of the United States and its outlying territories; therefore, the award is unrestricted. There is no charge for the solicitation documents; contact the Contracting Officer (jsotfp.cco@gmail.com) for copies of the plans for inspection without charge.

Proposal Submission:

1) Submit your proposals NO LATER THAN 10 January 2012, 4:30 pm, Philippine Standard Time.

2) All quotations delivered in response to this solicitation shall reflect the following information on the address label:

a. Solicitation Number W91NF9-12-Q-C0001

b. The legend, “To be delivered unopened to the Contracting Officer”, and

3) Submit your proposal to the following address:

MSgt Michael A. Holder

JSOTF-P/J4 – Contracting

Camp Navarro – Zamboanga City, Philippines

Email address: Michael.holder@jsotfp.socpac.socom.mil

The PAF’s piecemeal acquisitions

Friday , 6, January 2012 C-130, Philippine Air Force Leave a commentThe 305th Contracting Office of the AFP Procurement Service currently has P7,928,421.13 worth of bid invitations on PhilGEPS that dramatically illustrate the challenges that AFP logisticians face. Instead of establishing service support agreements with aircraft suppliers, the service is inviting potential suppliers to 18 individual bids for C-130 components. These appear in the table below.

For discussions about the difficulties that PAF has been experiencing with establishing logistical agreements and using GPPB mandated Order Agreement Lists, see here.

| Reference # / Solicitation # | Amount | Description |

| 1695835 / CP-11-547 | 400,063.00 | Procurement of 1 ea landing Gear Edge Cargo Ramp 353617-5 & 10 other L/I for use of C-130 arcft |

| 1695834 / CP-11-546 | 373,169.00 | Procurement of 1 ea Hose Assy, Hydraulic Suction Pump 698243-1 & 9 other L/I for use of C-130 arcft |

| 1695833 / CP-11-543 | 490,597.00 | Procurement of 2 ea tube Assy 370742-321 & 5 other L/I for use of C-130B arcft |

| 1695832 / CP-11-545 | 499,163.00 | Procurement of 1 ea Nuts, Vertical Stabilizer 68457-1812 & 17 other L/I for use C-130 acft |

| 1698265 / CP Nr S-11-251 | 705,000.00 | Procurement of 6 ea Fuel Nozzles 6890918/ 5232105-5H/ 6809611/5232212-7B for use of C-130 Acft |

| 1698264 / CP Nr S-11-250 | 394,606.25 | Procurement of 1 ea Ignition Unit, APU 899580-2 & 1 other L/I for use of C-130 Acft |

| 1698263 / CP Nr S-11-249 | 451,702.50 | Procurement of 2 ea Troop Seat ACA3102-17R & 4 other L/I for use of C-130 Acft |

| 1698262 / CP Nr S-11-248 | 422,206.25 | Procurement of 1 ea Ignition Unit, APU 899580-2 & 2 other L/I for use of C-130 Acft |

| 1698261 / CP Nr S-11-247 | 215,682.50 | Procurement of 4 ea Gasket Engine Generator LS35377-01 & 6 other L/I for use of C-130 Acft |

| 1698260 / CP Nr S-11-246 | 379,601.25 | Procurement of 1 ea Vane Segment Assy, Turbine 1st Stage 6847957/ 6847961 & 1 other L/I for use of C-130 Acft |

| 1698259 / CP Nr S-11-245 | 462,448.75 | Procurement of 6 ea Seal Labyrinth Rear Turbine 6844617/ 6897646 & 2 other L/I for use of C-130 Acft |

| 1698258 / CP Nr S-11-244 | 472,120.00 | Procurement of 3 ea Ring Air Seal 2nd Stage Vane 6844620/6892269 & 2 other L/I for use of C-130 Acft |

| 1698257 / CP Nr S-11-243 | 494,201.25 | Procurement of 6 ea Saddle Turbine 1st Stage 6852237/6856654 & 1 other L/I for use of C-130 Acft |

| 1698256 / CP Nr S-11-242 | 497,023.75 | Procurement of 7 ea Vane Segment Assy, Turbine 1st Stage 6847957/6847961 & 1 other L/I for use of C-130 Acft |

| 1698255 / CP Nr S-11-241 | 336,177.50 | Procurement of 1 ea Connector Plug MS3126F22-55PW & 2 other L/I for use of C-130 Acft |

| 1698254 / CP Nr S-11-240 | 353,513.75 | Procurement of 1 ea Wiring Harness 43631-1 & 2 other L/I for use of C-130 Acft |

| 1698253 / CP Nr S-11-239 | 481,562.50 | Procurement of 1 ea PTT Switch 421510 & 3 other L/I for use C-130 Acft |

| 1698252 / CP Nr S-11-238 | 499,582.88 | Procurement of 2 pails Lubticating Oil MIL-L-7808 & 16 other L/I for use of C-130 Acft |